Stainless Steel Lunch Box Press Machine

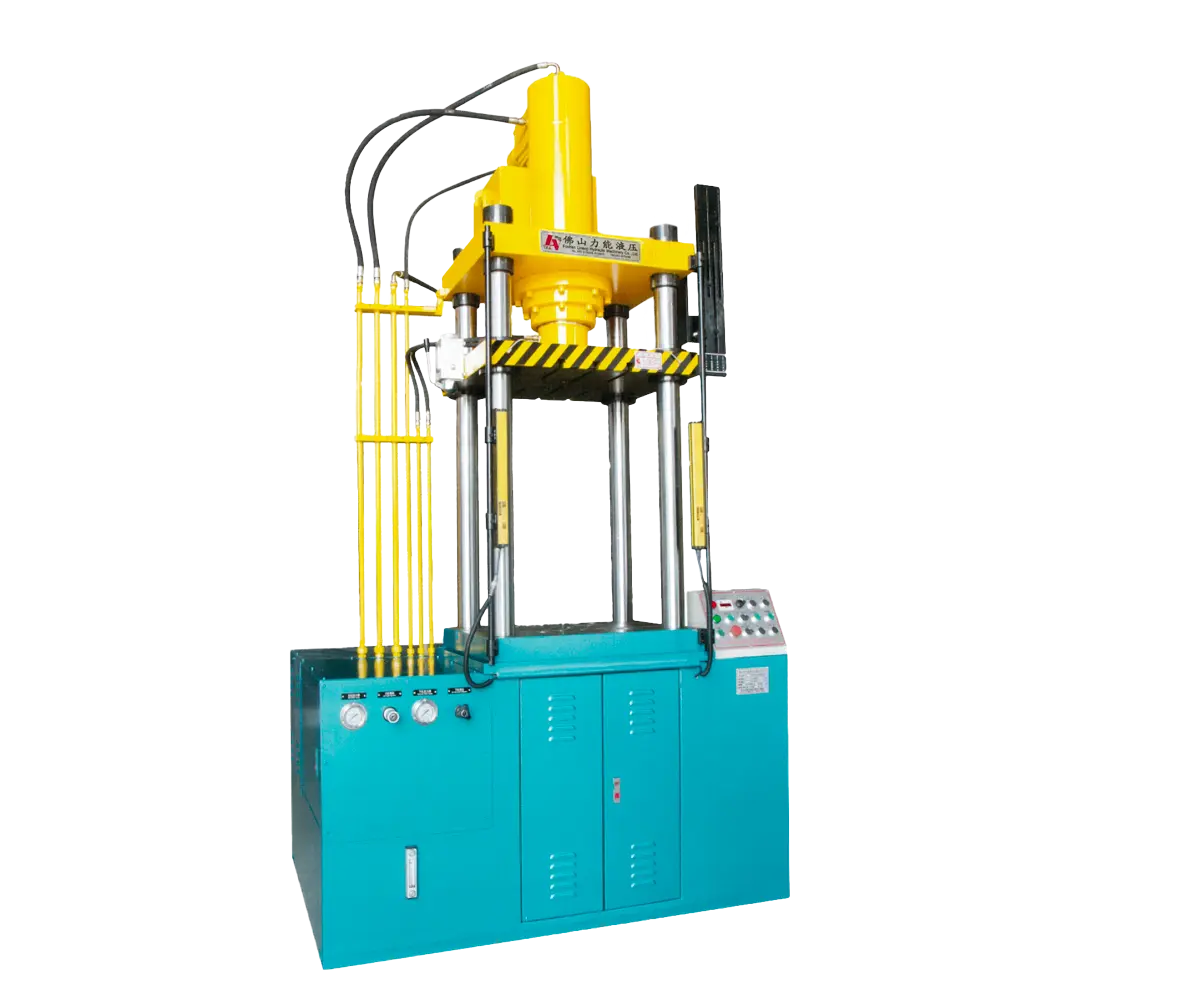

Best for SUS304 ≤0.8 mm. One-stroke deep drawing with fast cylinder; optional 6-axis robot + trimming line.

Upload your drawing · Get tonnage & mold suggestion in 24 hours

Each product section summarizes a proven forming solution, including the suitable process, press structure, and key technical parameters — helping you quickly determine the right machine configuration.

Best for SUS304 ≤0.8 mm. One-stroke deep drawing with fast cylinder; optional 6-axis robot + trimming line.

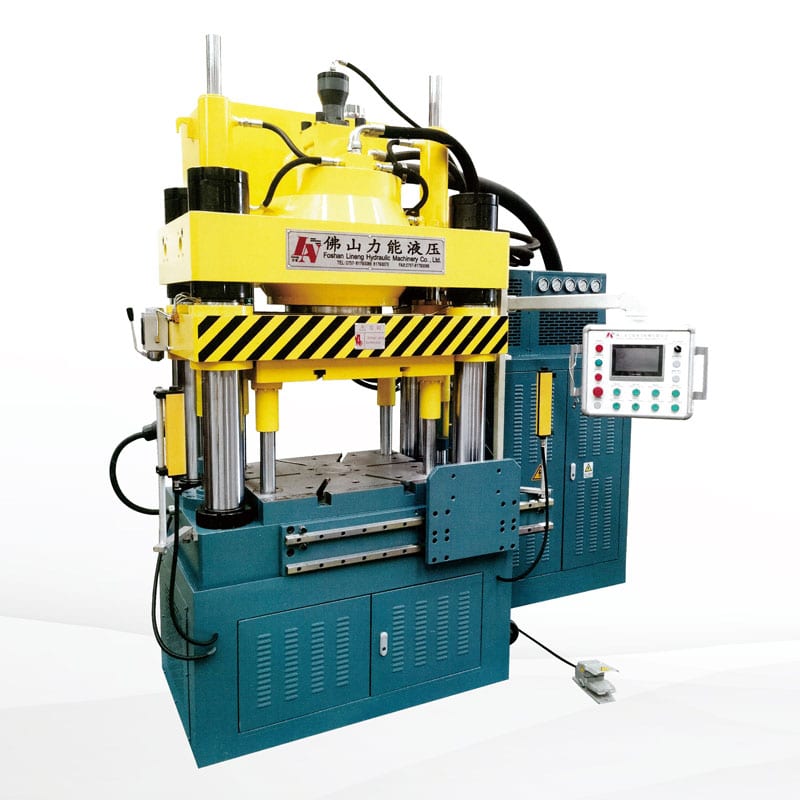

For metal vessel forming with uniform wall thickness and smooth surface. Suitable for kettles, cups, cookware bodies and GN pans.

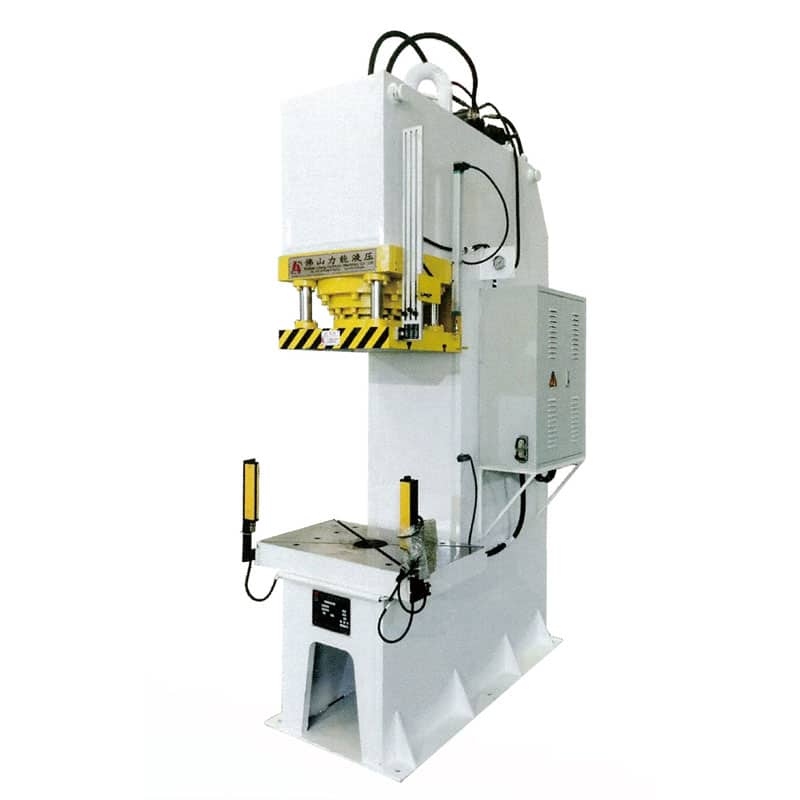

Precision forming for T-joints and copper tube branches; stable cycle and high repeatability for mass production.

Selected customer projects showing complete forming solutions — from tooling design to stable mass production.

Technical documents and reference materials to support press selection, tooling design, and forming process evaluation.

Tell us your target product. We’ll send tonnage & mold suggestions within 24 hours.

Tell us your target product. We'll send tonnage & mold suggestions within 24 hours.